Offer #1991

Forging railbound manipulator MKP 5 M

Specification:

Load capacity of manipulator (weight of ingot): 50 kN

Load moment: 100 kNm

Max. diameter of tongs rotation: 1300 mm

Max. opening of tongs: 750 mm

Max. height of peel shaft centreline over rail head: 800 mm

Max. parallel lifting of peel shaft: 600 mm

Distance from gripping jaws of tongs to the frame: 1600 mm

Adjustable rotational speed of tongs: 1-20 rpm

Adjustable travelling speed of machine: 1-60 m/min

Vertical travel speed of peel shaft: 5,6 m/min

Side shift of peel shaft: ±200 mm

Tilting of peel shaft:

-Upwards: 6 deg

-Downwards: 3 deg

Height of manipulator: 2500 mm

Overall dimensions in plan: 3400 x 8400 mm

Mass of manipulator: 39000 kg

Description:

The railbound non-rotatory manipulators are intended to handle elongated pieces during free forging in manual and automatic modes of operation in hydraulic presses.

Suspention system of the machines makes it possible to perform the next motions of peel shaft:

- parallel lifting and lowering;

- tilting upwards and downwards;

- side shift;

- rotation;

- axial travel relative to the carriage and return into central position.

The manipulators may be controlled in three modes of operation; manual, semi-automatic, automatic.

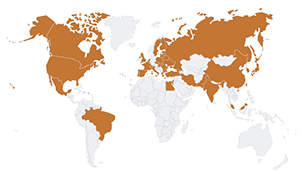

They are delivered to customers with ordinary or prolonged peels to be used either as components of plants with integrated control or without a plant to interact with presses from 5 to 31.5 MN and to be controlled from individual control desk.

Press the OFFER LINK button and then copy this link by pressing Ctrl + C or press the OFFER LINK button and then right mouse click on the selected text and choose `Copy`.